- +86 0512 6731 8995

- +86 13584869541

- qiujp@sipallwin.com

Electronics Factory

This product is used for stock-in and stock-out management of finished products, copper foil, BS/WIP.

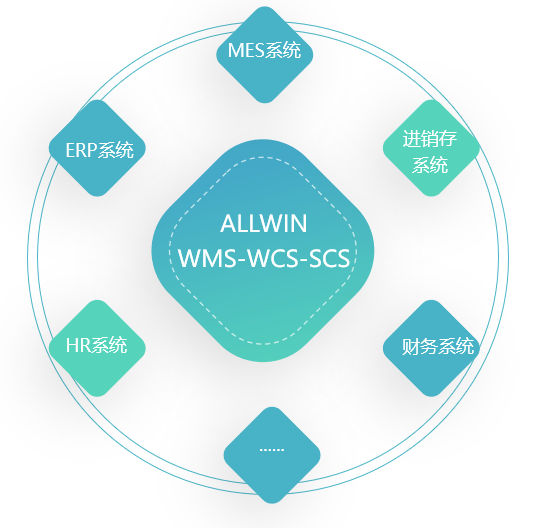

This system is not only used to complete the stock-in and stock-out management of finished products, materials, labels and special materials, but also can carry out statistical analysis on the stock-in and stock-out records, provide evidence for each operation, and generate complete statistical reports, which is conducive to the development of warehouse management work and truly realize intelligent warehouse

System management

(1) Department management : enterprise department basic information maintenance

(2) User management : operator basic information maintenance

(3) Role management : role information and permission information allocation

Basic information maintenance

(1) Warehouse information maintenance : warehouse and location basic information maintenance

(2) Material information maintenance : basic material information maintenance

Warehousing management

(1) Stock-in plan : synchronize the stock-in plan information from ERP, and further enter the stock-in task information

(2) Planned stock-in of finished goods warehouse : maintain the planned stock-in information of finished goods and further generate receipt tasks

(3) Finished goods stock-in: maintain the finished goods stock-in information and further produce stock-in tasks

(4) Planned stock-in of copper foil warehouse : maintain the planned stock-in information of copper foil and further generate stock-in tasks

(5) Copper foil warehouse stock-in : maintain the copper foil stock-in information and further produce stock-in tasks

(6) Planned stock-in of BS/WIP library : maintain the planned stock-in information of BS/WIP, and further generate the stock-in task

(7) BS/WIP library stock-in : maintain the planned stock-in information of BS/WIP, and further generate stock-in tasks

Stock-out management

(1) Stock-out plan : synchronize the stock-out plan information from ERP, and further enter the stock-out task information

(2) Planned stock-out of finished goods warehouse : maintain the planned stock-out information of finished goods and further generate stock-out tasks

(3) Finished goods warehouse stock-out : maintain the finished goods stock-out information and further produce the stock-out task

(4) Planned stock-out of copper foil warehouse : maintain the planned stock-out information of copper foil and further generate stock-out tasks

(5) Copper foil warehouse stock-out : maintain copper foil stock-out information and further produce stock-out tasks

(6) Planned stock-out of BS/WIP library : maintain the planned stock-out information of BS/WIP, and further generate stock-out tasks

(7) BS/WIP library stock-out : maintain the planned stock-out information of BS/WIP, and further generate stock-out tasks

Warehouse return task management

(1) Finished product warehouse return : maintain the finished product warehouse return document and further generate the stock-in task

(2) Finished product warehouse combined stock return : maintain the finished product combined stock return order and further generate the stock-in task

(3) Copper foil stock return : maintain the copper foil stock return order and further generate the stock-in task

(4) Copper foil assembly return : maintain the copper foil assembly return order and further generate the stock-in task

(5) BS/WIP warehouse return : maintain the BS/WIP warehouse return order and further generate the stock-in task

(6) BS/WIP combined stock return : maintain the BS/WIP combined stock return order and further generate the stock-in task

Inventory task management

(1) Finished goods inventory task : maintain the finished goods inventory sheet and further generate the stock-out task

(2) Finished goods inventory return task : maintain the finished goods inventory return document and further generate the stock-in task

(3) Copper foil inventory task : maintain the copper foil inventory sheet and further generate the stock-out task

(4) Copper foil inventory return task : maintain the copper foil inventory return order and further generate the stock-in task

(5) BS/WIP inventory task : maintain the BS/WIP inventory sheet and further generate the stock-out task

(6) BS/WIP inventory return task : maintain the BS/WIP inventory return order and further generate the stock-in task

Handling container management

(1) Empty tray stock-in : empty tray stock-in task maintenance

(2) Empty tray stock-out : empty tray stock-out task maintenance

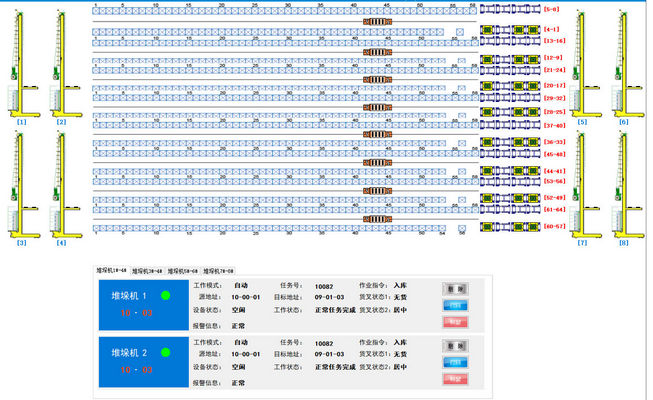

Task management

(1) Release of management tasks : maintain stock-in and stock-out tasks and further generate control tasks

(2) Control task management : control task maintenance

Inventory management

(1) Location status management : location status plan display, displaying location inventory information

(2) Location status correction : manually adjust the location status

(3) Inventory correction : inventory information modification

Statistical query

(1) Inventory query : inventory information query

(2) Stock-out/Stock-in query : stock-out/stock-in record query

(3) Stock-out/Stock-in comprehensive query : stock-out/stock-in summary statistics

(4) Material statistics : material summary statistics query

(5) System log query : system operation log query

Human Resources And Social Security

Human Resources And Social Security