- +86 0512 6731 8995

- +86 13584869541

- qiujp@sipallwin.com

Automotive

Vehicle commodity warehouse: Allwin participated in the construction of the first automated three-dimensional warehouse for large commercial vehicles in China, which greatly alleviated the demand for storage yard due to the increase in business volume. The project fills the gap in the construction of auto logistics automatic storage equipment and facilities in the country, and guides the extension of the port auto logistics chain, providing basic support for the development of the Yangtze River Delta economy to drive the automobile industry and economic society, and boosting the transformation and upgrading of the port.

Automotive parts and components Stereoscopic Warehouse:

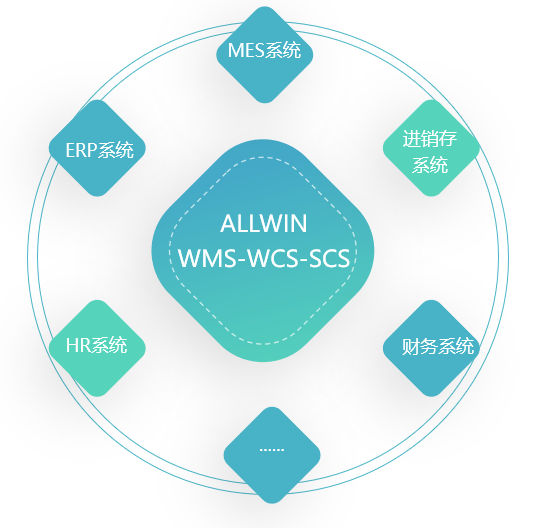

Ⅰ. Warehouse management system

Basic information maintenance

(1) Third party supplier maintenance: third party supplier information maintenance.

(2) Maintenance of vehicle model master information: synchronize vehicle model information from ERP, and maintain vehicle model information.

(3) Configuration information maintenance: synchronize configuration information from ERP and maintain configuration information.

(4) Location status setting: location status adjustment, location disable and enable, empty tray stock-out.

(5) Alarm code information maintenance

(6) Equipment Maintenance Record Maintenance

(7) Equipment maintenance parameters

Stock-in management : synchronize receipt information from MES and maintain receipt document information.

Stock-out management

(1) Stock-out Doc: synchronize stock-out information from MES, and maintain stock-out Doc information.

(2) Exceptional stock-out: seats exit along the exceptional stock-out route.

(3) PTR stock-out: test seat replacement stock-out.

(4) Manual shipping: the stock-out task manually changes the shipping route.

(5) Emergency handling: handling in the shipping queue after the stacker alarm and other abnormalities.

(6) Priority delivery: set priority delivery seats to avoid efficiency.

(7) Stock-out related settings: basic settings such as stock-out rules.

Check management

Inventory management

(1) Location status management: location status plan.

(2) Inventory freeze: freeze and unfreeze inventory information.

(3) Inventory report: inventory information statistics.

(4) Inventory alert: alert for inventory lower than safety stock.

(5) Stock age query: statistics of the length of seats in stock.

(6) Configure shortage query: inventory shortage alert.

Query statistics

(1) Operation log: query the equipment operation log.

(2) Alarm information query: equipment alarm information query.

(3) Equipment downtime statistics: statistics of equipment downtime duration.

(4) Equipment usage statistics: equipment usage statistics.

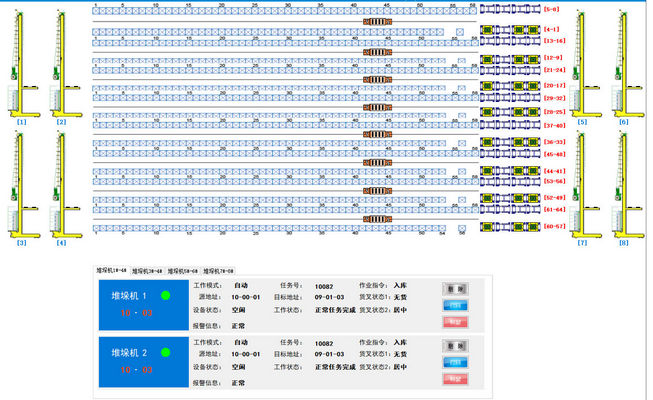

Ⅱ.Warehouse dispatching control system

(1) Communication management: PLC communication connection and disconnection.

(2) Task management: equipment scheduling task query, re-execution, status adjustment, posting and other operations.

(3) Task suspension and start: suspend and start equipment scheduling.

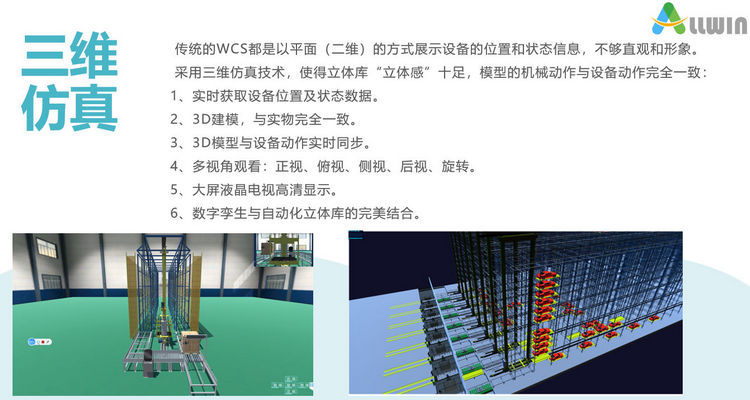

(4) Equipment monitoring: real-time animated display of equipment operation status.

(5) Alarm information: equipment alarm information query.

(6) Run Log: task execution log query.

Ⅲ.Shipping line management

(1) Maintain tray management: maintain tray repair information.

(2) Maintenance tray management: enter the tray maintenance data, and the maintenance tray is automatically discharged.

(3) Maintenance configuration: maintenance of tray maintenance rules.

(4) Operation log: SCS system control operation log.

(5) Shipping queue: query and maintain the seat shipping queue.

(6) Tray information: maintenance of tray position and other information.

(7) RFID information: RFID flow log query statistics.

(8) Line body quantity query: summary statistics of tray quantity and seat quantity of each line body.

(9) Stacking information maintenance: tray stacking information maintenance.

(10) Mode management: shipping line operation mode management.

(11) Manual management: manual release of each node.

(12) Communication status management: PLC communication status management.

(13) Equipment monitoring: real-time animated display of equipment operation status.

Human Resources And Social Security

Human Resources And Social Security